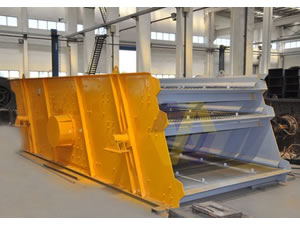

Vibrating Screen

Description

Vibrating screen (shaking screen) is mainly applicable in industries like mining, coal, smelt, building materials, refractory matter, light industry, chemical industry, medical and food processing field. It is most widely adopted by concentrating mill. According to different transmission gears, it can be divided into eccentric, inertia vibrating screening machine, self-fixed centre shale shaker and resonance screens.

Shaking screen is composed by vibrator, straining box, bearing or suspension system and transmission gear, etc.

Vibrating screen makes use of compound type spiral vibration generated by oscillator excitation to work. The rotary hammer makes the screen surface vibrate spirally. And the lower rotary hammer makes screen surface produce cone rotary vibration. The combined effect makes screen surface produce complex spiral type vibration. The vibration track is a complex space curve.

Features

Vibrating screen is characterized by high efficiency, light weight, complete and multi series and multi levels. Thus it can meet different requirements of clients.

Performance Parameters

| Model | Screen Layer | Screen Area (m2) | Sieve Pore Size (mm) | Max. Feed Size (mm) | Processing Capacity (m3) | Vibrating Power (r/min) | Double Swing (mm) |

V | Screen Surface (degree) | Screen Surface Size (mm) | Weight (kg) | Dimension(Length × Width × Height) (mm) |

| 2YK1225 | 2 | 6 | 4-50 | 400 | 8-60 | 800-970 | 8 | 5.5 | 20 | 1200 × 2500 | 2500 | 3040 × 1840 × 800 |

| 3YK1225 | 3 | 9 | 4-50 | 400 | 10-70 | 800-970 | 8 | 5.5 | 20 | 1200 × 2500 | 2850 | 3040 × 1840 × 1200 |

| 2YK1230 | 2 | 7.2 | 4-50 | 400 | 12-78 | 800-970 | 8 | 7.5 | 20 | 1200 × 3000 | 3000 | 3390 × 1900 × 800 |

| 3YK1230 | 3 | 10.8 | 4-50 | 400 | 13-80 | 800-970 | 8 | 7.5 | 20 | 1200 × 3000 | 3600 | 3537 × 1900 × 1200 |

| 2YK1237 | 2 | 8.88 | 4-50 | 400 | 15-86 | 800-970 | 8 | 7.5 | 20 | 1200 × 3700 | 3600 | 4090 × 1900 × 800 |

| 3YK1237 | 3 | 13.22 | 4-50 | 400 | 16-90 | 800-970 | 8 | 7.5 | 20 | 1200 × 3700 | 4200 | 4400 × 1950 × 1200 |

| 2YK1535 | 2 | 10.5 | 5-50 | 400 | 20-125 | 800-970 | 8 | 11 | 20 | 1500 × 3500 | 4890 | 4552 × 2250 × 900 |

| 3YK1535 | 3 | 15.75 | 5-50 | 400 | 21-125 | 800-970 | 8 | 11 | 20 | 1500 × 3500 | 5700 | 4552 × 2250 × 1600 |

| 2YK1545 | 2 | 13.5 | 5-50 | 400 | 22-150 | 800-970 | 8 | 15 | 20 | 1500 × 4500 | 5330 | 5400 × 2250 × 1600 |

| 3YK1545 | 3 | 20.25 | 5-50 | 400 | 22-150 | 800-970 | 8 | 15 | 20 | 1500 × 4500 | 5800 | 5400 × 2250 × 1700 |

| 2YK1548 | 2 | 14.4 | 5-50 | 400 | 22.5-162 | 800-970 | 8 | 15 | 20 | 1500 × 4800 | 5980 | 5300 × 2200 × 860 |

| 3YK1548 | 3 | 21.6 | 5-50 | 400 | 22.5-162 | 800-970 | 8 | 15 | 20 | 1500 × 4800 | 6600 | 5752 × 2200 × 1600 |

| 2YK1848 | 2 | 17.28 | 5-80 | 400 | 25-206 | 750 | 11 | 15 | 20 | 1800 × 4800 | 7080 | 6140 × 2470 × 1380 |

| 3YK1848 | 3 | 25.92 | 5-80 | 400 | 32-276 | 800-970 | 8 | 18.5 | 20 | 1800 × 4800 | 7600 | 6140 × 2710 × 1780 |

| 2YK1854 | 2 | 19.44 | 5-80 | 400 | 32-312 | 800-970 | 8 | 18.5 | 20 | 1800 × 5400 | 8150 | 6500 × 2600 × 1300 |

| 3YK1854 | 3 | 29.16 | 5-80 | 400 | 32-312 | 800-970 | 8 | 22 | 20 | 1800 × 5400 | 8840 | 6960 × 2600 × 1630 |

| 2YK2160 | 2 | 25.2 | 5-100 | 400 | 50-475 | 970 | 8 | 30 | 20 | 2100 × 6000 | 9780 | 7300 × 2950 × 2000 |

| 3YK2160 | 3 | 37.8 | 5-100 | 400 | 50-475 | 970 | 8 | 30 | 20 | 2100 × 6000 | 10800 | 7300 × 2950 × 2000 |

| 2YK2460 | 2 | 28.8 | 5-100 | 400 | 65-550 | 970 | 8 | 37 | 20 | 2400 × 6000 | 13600 | 7450 × 3230 × 1500 |

| 3YK2460 | 3 | 43.2 | 5-100 | 400 | 70-620 | 970 | 8 | 37 | 20 | 2400 × 6000 | 15600 | 7450 × 3230 × 1910 |

Choose and Buy

When choosing vibrating screen, the following parameters should be considered, such as swing direction angle, vibrational frequency, resonance amplitude, noise, power, bearing temperature, stress and modality, etc.

1. Test the vibrational frequency and direction angle.

2. Test the vibration frequency. Vibrating sensor can be put on the proper place of deck base. Collect and analyze the vibrating signals on the deck base so as to get the accurate working frequency.

3. Test resonance amplitude when vibrating screen stops.

4. Test the noise. Sound meter can be utilized to carry out such noise test.

5. Power meter is adopted to detect the actual power value.

6. Bearing temperature rise test. With the help of Laser temperature measurement meter, the tested value can be read out directly even when the screen does not stop. However, the data only can reflect the temperature change approximately.

7. Stress test.

8. Modal test. Users can have knowledge of natural frequency in each stage through modal test so that they can test whether working frequency of vibrating screen averts resonance point.

Maintenance

1. Daily Maintenance

1) Before Starting Vibrating Screening Machine

(1) Check the thick net and thin net.

(2) Check whether every group clamp is fastened.

(3) Check if V molding ring is damaged. If it is damaged, repair it timely so as to avoid material leaking.

2) In Operation

(1) Pay attention to whether there generates abnormal noise and whether the electric current is stable.

(2) Check whether the vibration is abnormal.

3. Cleanse it after each use.

Regular Maintenance of Vibrating Screening Machine

Check the thick net, thin net and spring to make sure they are not damaged. Check whether damage occurs due to vibration. Refill lubricating oil wherever necessary.

1. Make a support frame so as to hang the spare screen.

2. Check compression device and compress the loose parts.

3. Check the sealing strip as often as possible. Replace the damaged or defective parts timely.

4. The lattice should be taken out as often as possible. Check regularly whether the screen surface is damaged or uneven, the screen pore is blocked or not.

5. Check whether feedstock connection looses every shift. If the gap becomes big, crash will occur. Thus the vibrating screen will fracture.

6. Such shaking machine needs a overhauling once a year.

7. Check screen body support device every shift. Replace the damaged or over squashed rubber blanket.

Payment: T/T or L/C at sight

Mode of Transportation: By Motor in China, By Sea Abroad

LANTYPC Compressors is a professional manufacturer and exporter of vibrating screen (shaking machine) in China. Vibrating screening machine we provide is characterized by high quality, large crushing ratio, uniform feed size, simple structure, reliable operation, convenient maintenance and economical operating cost, etc. For detailed information about vibrating screening machine, please visit our website and contact us directly.

English

English Español

Español Русский

Русский