- Air Power Equipment

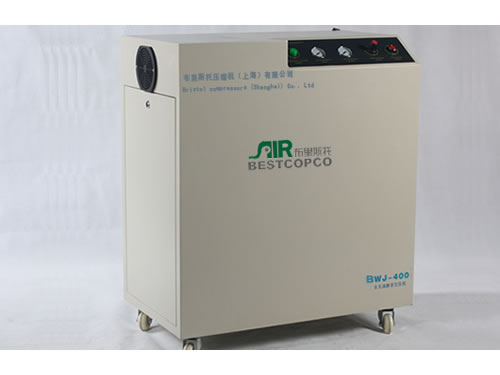

- Bristol Air Compressor

- Portable Screw Air Compressor

- Other Air Compressors

- Low Noise Air Compressor

- Frequency Conversion Air Compressor

- Explosion Proof Air Compressor

- Oil Field Using Air Compressor

- Drilling Use Air Compressor

- Vehicle Braking Air Compressor

- Windows and Doors Opening and Closing Use Air Compressor

- Textile Machinery Use Compressor

- Tyre Use Air Compressor

- Plastic Machinery Use Air Compressor

- Mining Use Air Compressor

- Medical Use Air Compressor

- Sandblasting Paint Spray Air Compressor

- Drill Rig

- Drilling Machine

- Jack Hammer

- Alloy Cables

- Pyroelectric Infrared Sensor

- Compressed Air Drying Machine

- Generator Sets

- Construction Hoisting Machinery

- Crushing Plant

- Mucking Loader

- Low Noise Air Compressor

- Low noise air compressor delivers excellent power (1/6 horse) with very little noise. Such low noise compressor is equipped with...

- Frequency Conversion Air Compressor

- Frequency conversion air compressor adopts main unit imported from Germany with big rotors and low speed, thus, it features high...

- Explosion Proof Air Compressor

- Explosion proof air compressor (explosion proof screw compressor) is equipped with electric protection devices, such as anti-explosion...

- Oil Field Using Air Compressor

- Working discharge pressures of the oil field using air compressors installed in oil fields are generally within 20 to 50 bar. Reciprocating...

- Drilling Use Air Compressor

- 1. Big And Strong Head Design, Using Good Material. The size of the head and the machine weight is bigger than any other manufactures. With...

- Vehicle Braking Air Compressor

- Vehicle braking air compressor (automobile brake screw air compressor) can be used in gas station, tire inflation, door and window on...

- Windows and Doors Opening and Closing Use Air Compressor

- 1. Windows and doors opening and closing use air compressor features non-phase intake air control adjustment and highly energy saving...

- Textile Machinery Use Compressor

- These textile machinery compressors are simply designed and can be customized into the extremely powerful ones to the one that can just...

- Tyre Use Air Compressor

- 1. Tyre use air compressor is specially equipped for pneumatic tools with high cost-effectiveness.2. Tyre piston air compressor features details...

- Plastic Machinery Use Air Compressor

- Plastic machinery use air compressor is extensively used in paint injection, electronics, textile, machinery, plastic tools, chemical...

- Mining Use Air Compressor

- 1. Mining use air compressor adopts specially designed screw main unit, which is stronger, more practical and reliable...

- Medical Use Air Compressor

- Medical use air compressor adopts American imported movement and main parts of medical air compressor, dry exporting air, absolutely...

- Sandblasting Paint Spray Air Compressor

- 1. Sandblasting paint spray air compressor is produced for equipped hardware pneumatic tools with high cost-effectiveness...

Other Air Compressor

Description

Air compressors are widely used in various fields like machinery, medical, textile, building materials, oil, chemical, light industry and food processing field, etc. They work by forcing air into a chamber whose volume is reduced to compress the air. Piston-type air compressors use this principle by pumping air into an air chamber through the use of the constant motion of pistons. They use one-way valves to guide air into a chamber, where the air is compressed. The most commonly used air compressors are screw compressor (single screw type and twin screw type), piston compressor, compressors and so on. Besides, many specially used compressors are available in our company, such as low noise compressor, frequency conversion screw compressor and textile machinery air compressor, etc.

Features

1. Computer Control

Air compressors are controlled by computer. Thus they are powerful with a variety of monitoring points. Data information can be successively displayed on large screen (four lines). Besides, with computer control, air compressors can achieve field programming function. In addition, they feature automatic error budgeting skills, automatic recording and centralized control functions, which makes it easy to operate them.

2. Unique Design

The internal part is divided cold and hot side. Namely, the water in hot side oil separator is not easy to condense in oil in the form of steaming water, which guarantees the quality of the lubricating oil. And at the same time, the air inlet on the cold side can intake the air with temperature as low as possible. The air inlet is set on the rear top of cold side electrical cabinet, which makes it possible to intake low temperature air with similar discharge pressure. Therefore, the efficiency of air compressors is greatly improved.

3. Direct Coupling

Equipped with direct coupling, the impact on air compressors and vibration has been greatly reduced. And the cooling fan endows the direct coupling with long service life.

4. Large Internal Space

The inside space of air compressors features good air fluidity, high top and large maintenance space. Besides, every process has specially designed mechanism, from the replacement of oil filter, air filter and oil gas separator to the cleaning of heat exchanger. Even one operator can finish the whole process.

Advantages

1. The most complete air compressors solutions are available for clients with different requirements.

2. Our compressor products are superiorly manufactured, guaranteeing their reliability and economical efficiency.

3. Our service support is of the highest quality; our ability to help our customers save energy is second to none and we are always at the forefront of market innovations.

4. We have supplied products into some of the toughest industrial, commercial and mining environments, making our Air Compressor a well rounded product.

Attention

1. Keep lubricating oil within the scope of the scale. Before operating air compressor, users should make sure the oil level is not lower than the scale value.

2. Check all the moving parts and make sure they are flexible. Examine all the connecting parts, lubricating system, electromotor and electric control equipment and make sure they are fastened, normal, safe and reliable.

3. Before starting up the air compressors, protective devices and safety accessory should be inspected so as to guarantee that they are complete and in good condition.

4. Check whether the venting pipe is unblocked.

5. Connect water source and open all the inlet valves so as to make the cooling water unimpeded.

Maintenance

1. Replace air filter.

2. Replace oil filter.

3. Replace oil-gas separator.

4. Replace lubricant.

LANTYPC Compressors is a professional supplier of frequency conversion screw compressor in China. We provide high quality air compressors with multi-features for sale. We have strict quality checking system so as to guarantee the quality of our products. Bristol (Shanghai) Co., Ltd. never compromises to sacrifice quality to get low price. For detailed information about air compressors, please visit our website and contact us directly.

English

English Español

Español Русский

Русский