No Heat Regenerative Adsorption Compressed Air Dryer

Description

Heatless desiccant dryer or heatless regenerative air dryer makes use of special micropores in desiccant to absorb hydrone in the air through capillary action and dehydrate the absorbed water through relieving pressure absorbing excess heat and warming. Heatless desiccant dryer is usually made into bi-cylinder form. Controlled by programming controller, two cylinders work alternatively. One cylinder absorbs water, and the other desorbs and regenerates continuously.

Features

1. Heatless desiccant dryer (no heat regenerative adsorption compressed air dryer) has stable gas pressure dew point.

A. Heatless regenerative air dryer adopts reasonable tank design, keeping the contact time of 4.8 seconds so as to meet the dew point of outlet air.

B. 30% desiccant is preserved to make up for natural ageing desiccant so as to guarantee the drying effect.

C. Heatless desiccant dryer employs large diffuser so as to ensure that the air can uniformly go through desiccant layer and to eliminate channeling phenomenon.

2. Purge air consumption is below 12%.

A. Heatless regenerative air dryer makes use of tank design, which saves 95% adsorption heat. And the stored heat is used to regenerate the air temperature in regenerative process and improve the desorption ability.

B. Reverse convection is utilized in drying and regenerating process so as to guarantee the best effect when wet air goes through dry desiccant.

C. Resurgent gas consumption is adjustable according to running and loading demands.

3. Desiccant features long service life.

A. With reasonable tank size, the flow speed and time can be maintained in optimal state. The desiccant performance is maximized.

B. With proper system configuration, the oil and heavy pollution are unoiled before the air goes through cylinder so as to avoid polluting desiccant layers.

4. Heatless desiccant dryer (no heat regenerative adsorption compressed air dryer) adopts imported butterfly valve and advanced and reliable microcomputer program controller, endowing heatless regenerative air dryer with self-clocking and automatic shifting features. Therefore, it works stably, not affected by power grid, voltage or electric field, etc.

5. Reasonable switch time design guarantees stable outlet pressure.

6. Heatless desiccant dryer features convenient installation.

Working Condition and Technical Indicator

Purge Air: ≤ 12% to 15%

Working Pressure: 0.6 MPa to 1.0 MPa

Inlet Oil Content: ≤ 0.01ppm

Pressure Loss: ≤ 0.03 MPa

Outlet Air Pressure Dew Point:-20℃ to -40℃

Desiccant: Activated Alumina or Molecular Sieve

Working Period: T= 4 min to 20min

Inlet Temperature: 0℃ to 45℃

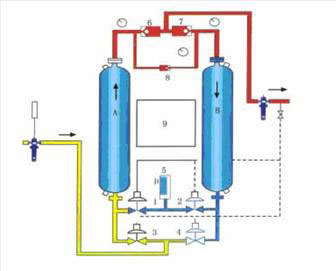

A, B Absorber

1, 2, 3, 4 Changeover Valve

5. Silencer

6, 7 Check Valve

8. Throttle Valve

9. Programming Controller

Parameters of Heatless Desiccant Dryer

| Model | Air Processor (Nm3/min) | Air Interface Size | Dimension (mm) | Weight (kg) | ||

| Length | Width | Height | ||||

| SAD-1WXF | 1.2 | ZG1 | 700 | 370 | 1062 | 180 |

| SAD-2WXF | 2.4 | ZG1 | 700 | 370 | 1483 | 300 |

| SAD-3WXF | 3.8 | ZG1.5 | 850 | 470 | 1655 | 350 |

| SAD-6WXF | 6.5 | ZG2 | 1000 | 570 | 1965 | 510 |

| SAD-10WXF | 10.7 | ZG2 | 1250 | 620 | 2002 | 720 |

| SAD-13WXF | 13.5 | DN65 | 1250 | 620 | 2120 | 780 |

| SAD-20WXF | 25 | DN80 | 1250 | 745 | 2354 | 1280 |

| SAD-30WXF | 35 | DN100 | 1300 | 745 | 2595 | 1760 |

| SAD-40WXF | 45 | DN125 | 1400 | 915 | 2595 | 2200 |

| SAD-50WXF | 55 | DN125 | 1840 | 1075 | 2595 | 2600 |

| SAD-60WXF | 65 | DN125 | 1840 | 1075 | 2595 | 3100 |

| SAD-80WXF | 85 | DN150 | 2300 | 1265 | 2595 | 4100 |

| SAD-100WXF | 110 | DN150 | 2800 | 1265 | 3200 | 5200 |

| SAD-160WXF | 160 | DN200 | 2800 | 1320 | 3200 | 6000 |

LANTYPC Compressors is a professional supplier of heatless desiccant dryer (no heat regenerative adsorption compressed air dryer) in China. We provide high quality heatless regenerative air dryer with multi-features. We have strict quality checking system so as to guarantee the quality of our products. We never compromise to sacrifice quality for low cost. For detailed information about heatless desiccant dryer, please visit our website and contact us directly.

English

English Español

Español Русский

Русский