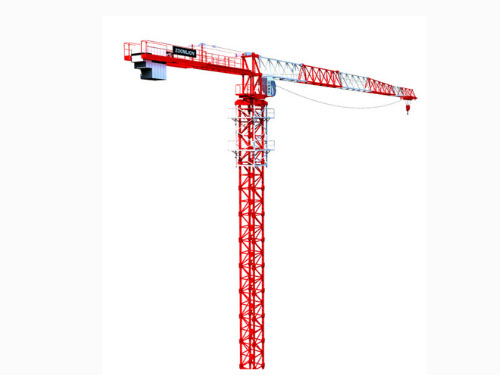

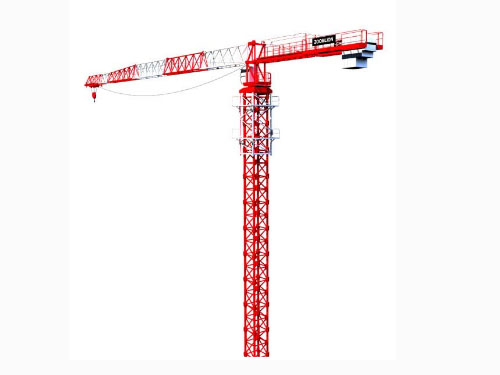

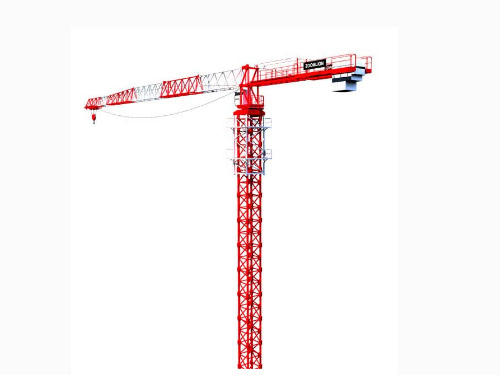

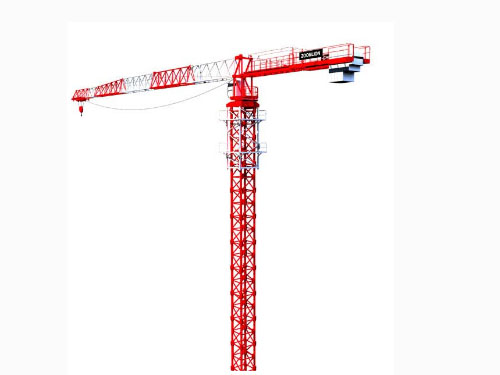

Flat-Top Tower Crane

Description

Flat-top tower crane can be used crosswise by multi cranes at the same site. Its arm rest and crane house are in T form. Its marked feature is that the lifting arm is connected with balance arm, without tower head or pull rod. Besides, it features horizontal and rigid upper structure. This flat-top tower crane mainly consists of metal structure part, operating mechanism and drive control system. It is mainly applicable in industrial and civil construction field, especially widely used in power station construction and venue construction.

Advantages

Such tower crane features novel design, safe and reasonable structure, high reliability, anti-fatigue ability and shock resistance.

1. Steel structure endows tower crane with long working life and safety.

The upper structure is horizontal and rigid. With no lift arm pull rod, the arm frame section size is bigger than that of common one. Flat-top tower crane features simple load-carrying capacity. It only works under downward loading force. Its arm cannot be affected by alternating stress vertically and horizontally, which greatly improves its working life and safety. When working, especially in sudden stop or quick rotation, flat-top tower crane features small deformation, stability and safety. The cantilever crane and balance arm can guarantee the strength and stiffness of themselves, which largely enhances their service life and makes safer structure.

2.It is characterized by low installation and debugging.

Flat-top tower crane with no pull rod has reduced the tower height. It is applicable for crossover operations of group towers and greatly improves working efficiency. In addition, such tower crane features small unit weight and low installation height. This can shorten the distances between tower bodies, save the space and cost.

3. Cantilever crane has no pull rod. The connecting design is more simple and direct. This design, to large extent, makes it convenient to change and open arms in the air. Besides, such flat-top tower crane avoids complexity and high risk of dismantle the pull rod and saves dismounting cost.

It has the feature of easy and convenient installation. The number of cantilever crane can be reduced or increased accordingly so as to satisfy the requirements of different constructions. Such flat-top tower crane is more suitable for disassembly under crossover operation of group towers and limited construction condition.

4. It adopts modular design.

With modular design, we provide a wide selection of flat-top tower cranes so as to meet the requirements of clients.

Performance

1. Tower crane is equipped with no tower head or pull rod bearing. It features compact working mechanism, simple and good-looking appearance and small coefficient of dead weight.

2. Flat-top tower crane has large working space.

3. The tower body is connected by angle steel and fishplate. This makes convenient transportation and storage, good manufacturability, reasonable load-carrying capacity and quick installation.

4. Without tower head, flat-top tower crane has strong anti-interference capacity and can be used crosswise by multi cranes at the same site. It adopts coat rack side lifting shoring.

5. Flat-top tower crane makes use of advanced electronic control system, which can achieve stepless frequency control, flexible and steady operation and low power consumption.

6. Suspension arm adopts segmented cross section method to gradually reduce the weight so as to achieve average load-carrying capacity and to be free from foozle influence. Thus, the high use ratio is achieved.

7. The top of tower crane can be easy and quick for installation. The arm rest can carry out installation in section with small mounting height.

Payment: T/T or L/C at sight

Mode of Transportation:By Motor in China, By Sea Abroad

LANTYPC Compressors is a specialized manufacturer and supplier of flat-top tower crane in China. We provide nationwide quality assurance for our cranes. We have six large service management areas all across China and possess 108 real stores. We will inspect the machine every three months. If we are told abnormal problems, we will provide solution within two hours or send professional staff to arrive at the scene within 0.5 to 24 hours in China.

English

English Español

Español Русский

Русский

.jpg)

.jpg)